Oracle this week announced it will extend the reach of machine learning algorithms and related artificial intelligence (AI) applications into the realm of manufacturing.

Ramchand Raman, vice president of product development for Oracle, says Oracle Adaptive Intelligent Applications for Manufacturing will employ machine learning and AI to process vast amounts of data to identify issues before they occur while also serving to improve overall operational efficiency.

Oracle has already developed 150 key performance indicators (KPIs) for manufacturing firms that will serve as the baseline for which it will analyze manufacturing processes using machine learning algorithms and AI models. Over time, customers will be able to add their own KPIs, machine learning algorithms and AI models, says Raman.

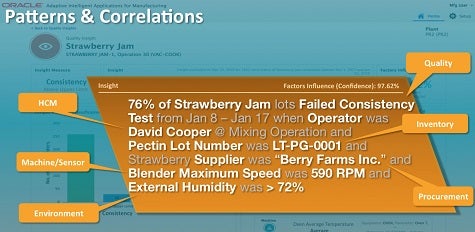

Specifically, Oracle Adaptive Intelligent Analytics for Manufacturing identifies patterns and correlations across variables such as manpower, machine, method, material and other management-related information. Users align these insights with manufacturing business metrics such as yield, quality, cycle time, cost, scrap, rework, and returns to identify root causes of issues. Machine learning and AI models then layer a predictive analytics capability on top of all the data being collected to identify yield, defects, scrap, rework, cycle time and the costs associated with specific processes. Raman says that rather than relying on a human to set up a query to discover that information, AI models will automatically surface it. There’s even a “smart recall” analysis tool to provide backward and forward tracing of products and processes to identify products, services and customers that might be impacted by a specific issue.

Raman says Oracle Adaptive Intelligent Applications for Manufacturing will be consumed primarily as a software-as-a-service (SaaS) application. But Oracle will make available editions that can be deployed as a “Cloud at Customer” option as well. Pricing for the cloud service starts at $100 per user per month, with a minimum number of 30 users required.

“We wanted to make the application very accessible starting at $3,000 a month as a SaaS application,” says Raman.

The primary benefit of that approach is that manufacturing firms can start taking advantage of machine learning algorithms and AI models immediately versus spending three to four years trying to build an equivalent capability on their own, says Raman.

Because manufacturing is largely based on a finite number of variables, it makes an ideal application for applying AI against structured, semi-structured and unstructured data. The issue with analyzing that data has been finding a way to centralize it in a repository that creates a large enough pool of data to apply machine learning algorithms against.

It remains to be seen exactly what impact this will have on manufacturing quality and the number of people required to build anything. Most of the analysis that can be provided by AI models isn’t being provided today because there isn’t enough data in a central place to analyze, let alone finding the data scientists capable of making sense of it. But as usage of AI continues to expand, it’s already clear that manufacturing at any level of scale will soon never be the same again.